Phone: (740) 432-2969 - E-mail: info@LMIDesign.com

>> Production Development

>> Production

>> Rapid Production Tooling

>> Rapid Prototyping

>> Production Assembly

Product Development

MORE IMAGES

- · Bottle Clip Drawing

- · Gas Meter Enclosure Open

- · Gas Meter Enclosure Closed

- · Industrial Design Concept Coffee Filter

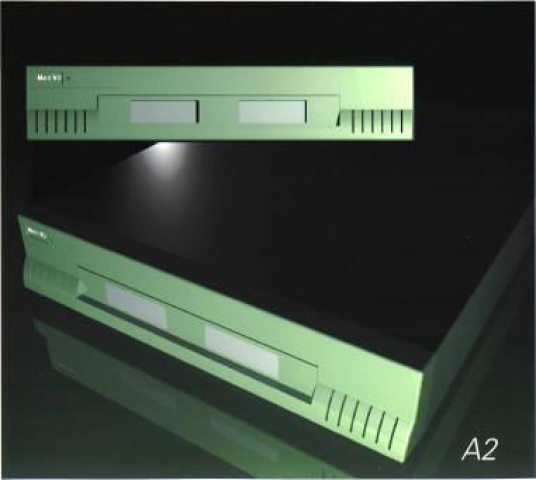

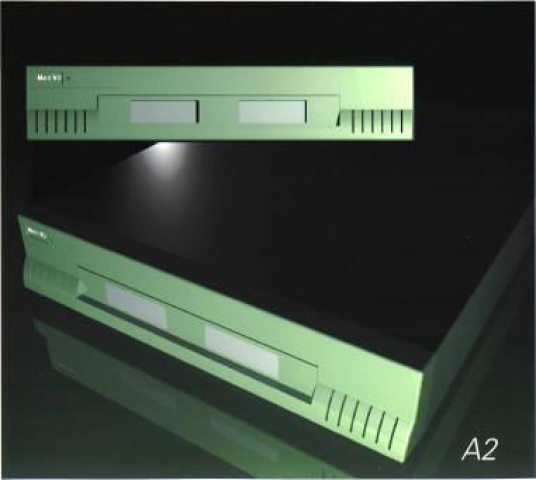

- · Industrial Design Concept Computer Housing

- · Industrial Design Concept Handle

- · Tool Assembly Drawing

DOWNLOADS

-

ABS HI-121 Material

(PDF, 19KB)

-

Detail Drawings

(PDF, 1706KB) -

GELOY CR7500

Material

(PDF, 38KB)

-

Nylon

6-PA-RTP-299AX100901 Material

(PDF, 43KB) -

PAC J-3

30 Glass Filled Nylon Material

(PDF, 275KB) -

Polyetherimide

PEI-GP1 Material

(PDF, 125KB)

-

Rynite FR543 NC010

Material

(PDF, 119KB)

Leyshon Miller Industries offers product development services based on profound knowledge

and

experience in developing the product from the initial idea through the product creation. We

are

specialists in product development with experience in research, design, conceptual drawings,

prototyping, engineering and production. In product development, we launch innovative

products

that meet market needs by transforming innovative ideas into manufactured products.

We develop prototypes that look aesthetically pleasing and function like the final products as part of the product development. We can carry out complete assembly services and have immense experience in developing products such as welding units, gas sensing devices, medical products and tools for a number of manufacturers.

Leyshon Miller Industries follows the ISO certification qualifications since quality products and services are our main priority. We provide the critical link in making successful product development by saving development costs with less design iterations using our expert engineering team. We can also assist you in acquiring patents, trademarks and handle final packaging.

Our product development services span to :

Our product development process will provide customers with the best quality products in the most efficient process. We will supply all design files, pilot units and production parts after the completion of the project. Depending on the design and requirements, parts can be produced quickly in a wide range of materials that meets your specifications.

We develop prototypes that look aesthetically pleasing and function like the final products as part of the product development. We can carry out complete assembly services and have immense experience in developing products such as welding units, gas sensing devices, medical products and tools for a number of manufacturers.

Leyshon Miller Industries follows the ISO certification qualifications since quality products and services are our main priority. We provide the critical link in making successful product development by saving development costs with less design iterations using our expert engineering team. We can also assist you in acquiring patents, trademarks and handle final packaging.

Our product development services span to :

- Industrial Design Concepts

- Mechanical Engineering Design

- Engineering Analysis

- Assembly and Mechanism Engineering

- Fully Detailed Drawings

- Material and Process Selection

Our product development process will provide customers with the best quality products in the most efficient process. We will supply all design files, pilot units and production parts after the completion of the project. Depending on the design and requirements, parts can be produced quickly in a wide range of materials that meets your specifications.

larger image

larger image

Engineering Application Software

- SDRC Master Series

- Autocad

- Cadkey

- Powermill By Delcam

- Solid Edge

- Solidworks

- Algor

Prototype

- FDM Stratasys

- Precision CNC Machining

Mold Building Support

- Makino S56 CNC high speed milling machine 13,000 rpm

- Makino S56 CNC high speed milling machine 20,000 rpm

- Milltronics VM-24 CNC

- Makino SNC64 High Speed Carbon Mill

- Makino EDNC EDM Machine

- Sharp Vertical Milling Machines

- Sharp Lathe

- Surface Grinders

- Lincoln Electric Welder

- Radial Drill

- Spotting Press

Production

- 50-Ton Van Dorn Injection Molding Machine

- Tiebar Space: 10.25 x 12.375

- Platen: 19 x 17.625

- Max Opening: 20.5

- Min Close: 7

- Screw: 3 Oz.

- Hydraulic, Eject

- 88-Ton Milacron Injection Molding Machine

- Tiebar Space: 16.4 x 14.56

- Platen: 21.25 x 21.25

- Max Opening: 29.5"

- Min Close: 9.375"

- Screw: 3.8 Oz.

- Hydraulic Eject

- 150-Ton Van Dorn Injection Molding Machine

- Tiebar Space: 18 x 15 1/2

- Platen: 27 1/2 x 24 1/2

- Max Opening: 27 1/2"

- Min Close: 9"

- Screw: 5 Oz.

- Hydraulic Eject

- 300-Ton Van Dorn Injection Molding Machine

- Tiebar Space: 25 x 25

- Platen: 37.25 x 37

- Max Opening: 48"

- Min Close: 13"

- Screw: 28 Oz.

- Hydraulic Eject/Core Pull

- 375-Ton Natco Injection Molding Machine

- Tiebar Space: 26 x 26

- Platen: 39 x 39

- Max Opening: 40"

- Min Close: 8"

- Screw: 40 Oz.

- Hydraulic Eject/Core Pull

- Auxiliary Equipment - Thermolators, Chiller, Dryers, Grinders & Loaders

Import File Formats

- IGES

- VDA

- SET

- STEP

- Cad Key

- Auto Cad

- Parasolids

- Pro-E

- Solidworks

- Solidedge

- Cadkey

Export File Formats

- IGES

- VDA

- SET

- Step

- Cad Key

- Auto Cad

- VRML

- Parasolids